HEAT TREATMENT PLANTS

Fully-integrated production process

About our Heat Treatment Facilities

At Gautschi, we incorporate highly-efficient recuperative burners with minimized heat losses into our heat treatment furnaces – benefitting both the environment and the customer. Modern technologies, state-of-the-art designs, skilled manufacturing and professional installation, as well as competent commissioning, ensure the fulfillment of relevant metallurgical requirements. PLC control systems and industrial computers facilitate the operation of Gautschi heat treatment facilities and make fully-automatic production possible.

Pusher Type Furnaces

References with furnace charges up to 810 t

- Tailor-made handling equipment

- Highly-efficient self-recuperative burners

- Sophisticated nozzle system for excellent temperature uniformity and short heat-up times

- Patented sliding shoe system ensures smooth slab transport

- Low energy consumption

- Powerful cooling system for homogenizing process

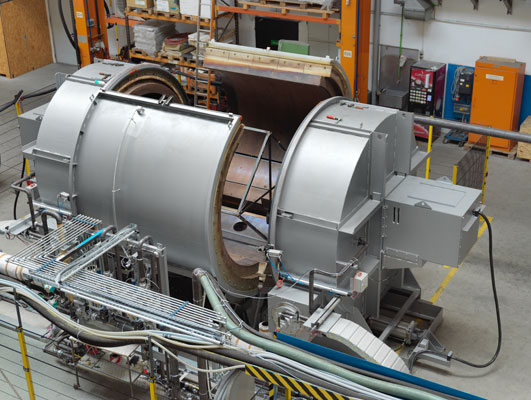

Chamber Furnaces

For strip and foil coils, billets and slabs

- Protective gas annealing

- Nozzle system for high heat transfer

- Self-recuperative burners

- Homogenization of billets and slabs

- Supplied with fully-automatic charging machines

Soaking Pit Furnaces

References up to 470 t furnace load

- Flexible charging for variety of slab dimensions

- Highly-efficient self-recuperative burners

- Strong, spring-loaded supporting structure

- Individually-controlled furnace zones

Compact Coil Furnace

Next generation single coil furnace

- Energy savings of 75 %

- Inert gas savings of 55 %

- Flexible production

- Easily-adaptable design

- Short installation time

- Integration into existing coil handling systems

- Furnace array can be equipped with an automatic handling system

- Reduced workshop building height required

- Fully-automated (operator-free) plant possible

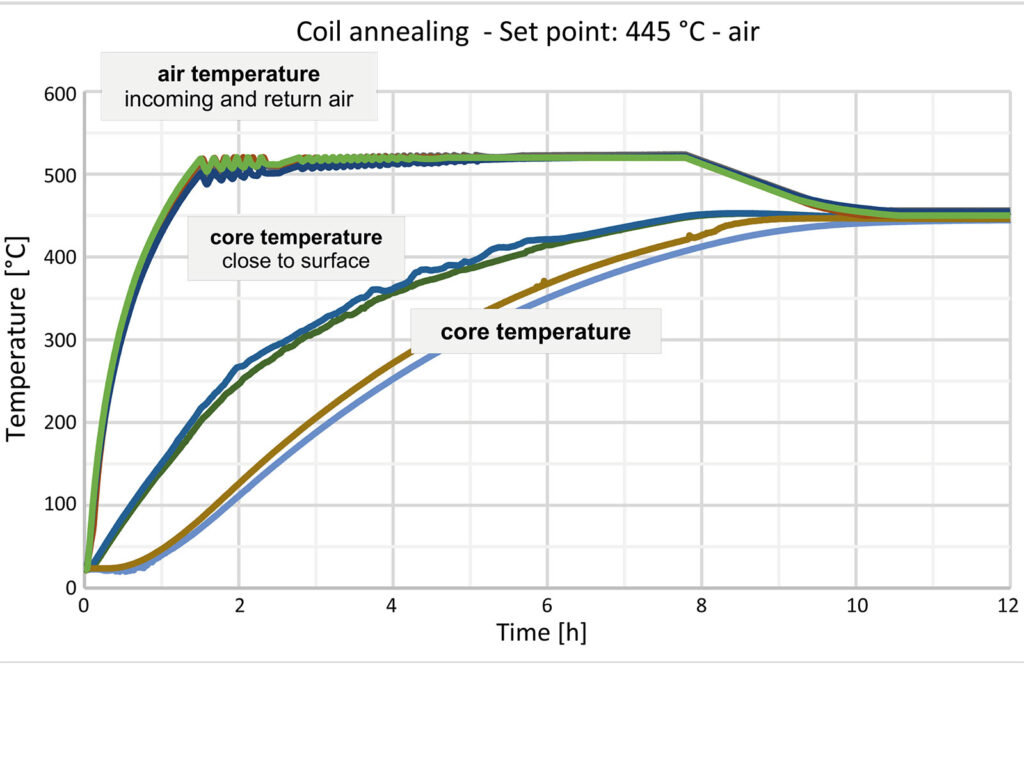

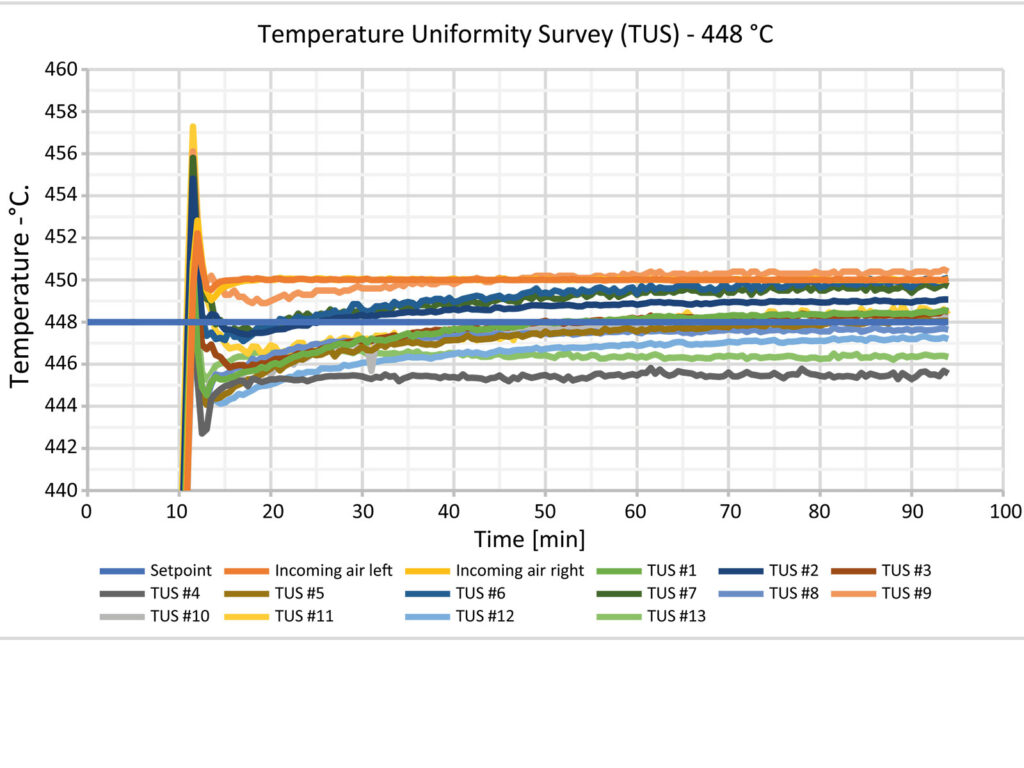

Gautschi incorporates highly-efficient recuperative burners with minimized heat losses into its heat treatment furnaces, to benefit both the environment and the customer. High-convection heat transfer and optimized process technology ensure the best anneal results, combined with maximum throughput.