Pacific Precision Forging (PPF), Chairman Unit of CCMI (Confederation of Chinese Metalforming Industry), has mastered advanced core technologies of gear precision forming tooling design, development and manufacturing. As a global leading supplier of precision forging gears, PPF adopts cold, warm and hot precision forging technologies to manufacture automotive gears professionally. PPF won VW Group Award 2020 and GKN Global Competitiveness Award 2021.

Under the background of expanding aluminum alloy forging capacities, PPF has decided to invest in its own aluminum foundry for producing high quality forging billets needed for down-stream aluminum alloy forging process.

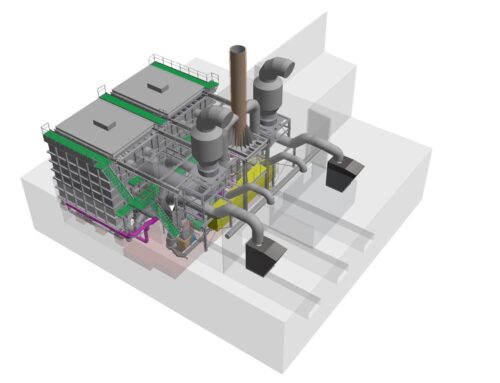

HPI as the market leader for horizontally casted forging billets and with Gautschi’s high reputation for efficient and reliable liquid metal furnaces are able to offer an attractive solution to PPF for the design, engineering, manufacturing, supply, installation supervision, commissioning, testing and training of new equipment: a New Generation Horizontal Casting Machine Type 3000, 2 Stationary Rectangular Melting Furnaces with 20t capacity and 1 Tilting Rectangular Casting Furnace of 23t capacity. All furnaces will be supplied with Gautschi Burner Technology whereas a highlight is the newest generation of Gautschi Regenerative Burners for the 2 Melting Furnaces. The entire system shall be operational in the beginning of 2023.

The plant and equipment have been selected and designed for excellent operability, quality and reliability (Efficiency, Speed, Quality & Cost), incorporating all requirements for casting workshop safety, explosion risk management and advanced automation.